Aluminum pharmaceutical aerosol can

-

Quantity5000 - 10000:$0.2

-

Product Information:

Material: 99.7% aluminum

Sealing Type: Pump sprayer

Filling diameter (mm): 1 inch , 20mm

Interior coating : Epoxy Resin

Capacity (ml): 5 - 300

Diameter (mm): Ø22 - Ø59

Height (mm): 58 - 180

Surface finish: Polishing, color coating0.22 USD per bottle for quantities starting from 5,000 units.

0.20 USD per bottle for quantities starting from 10,000 units.

Please note: This pricing applies to bottle with a diameter of 40mm. Unit prices will change based on specific specifications and custom requirements.

Free Shipping: 10,000 units.

- Add to cart

Design service: Design, Custom Brand as customer required

Color: as customer required printing (1 to 8 colors)

MOQ: 30.000 PCS (negotiate)

Usage: waterproof bandage spray, nasal hygiene spray, pain relief spray. etc..

Delivery time: 20 - 30 days

The Optimal Solution for the Pharmaceutical Industry: Why Aluminum Spray Bottles Outperform Traditional Plastic Containers

While plastic packaging has been a popular choice due to its low cost and light weight, it presents numerous critical weaknesses for pharmaceutical products, especially in spray form.

The Risks of Using Traditional Plastic Packaging

-

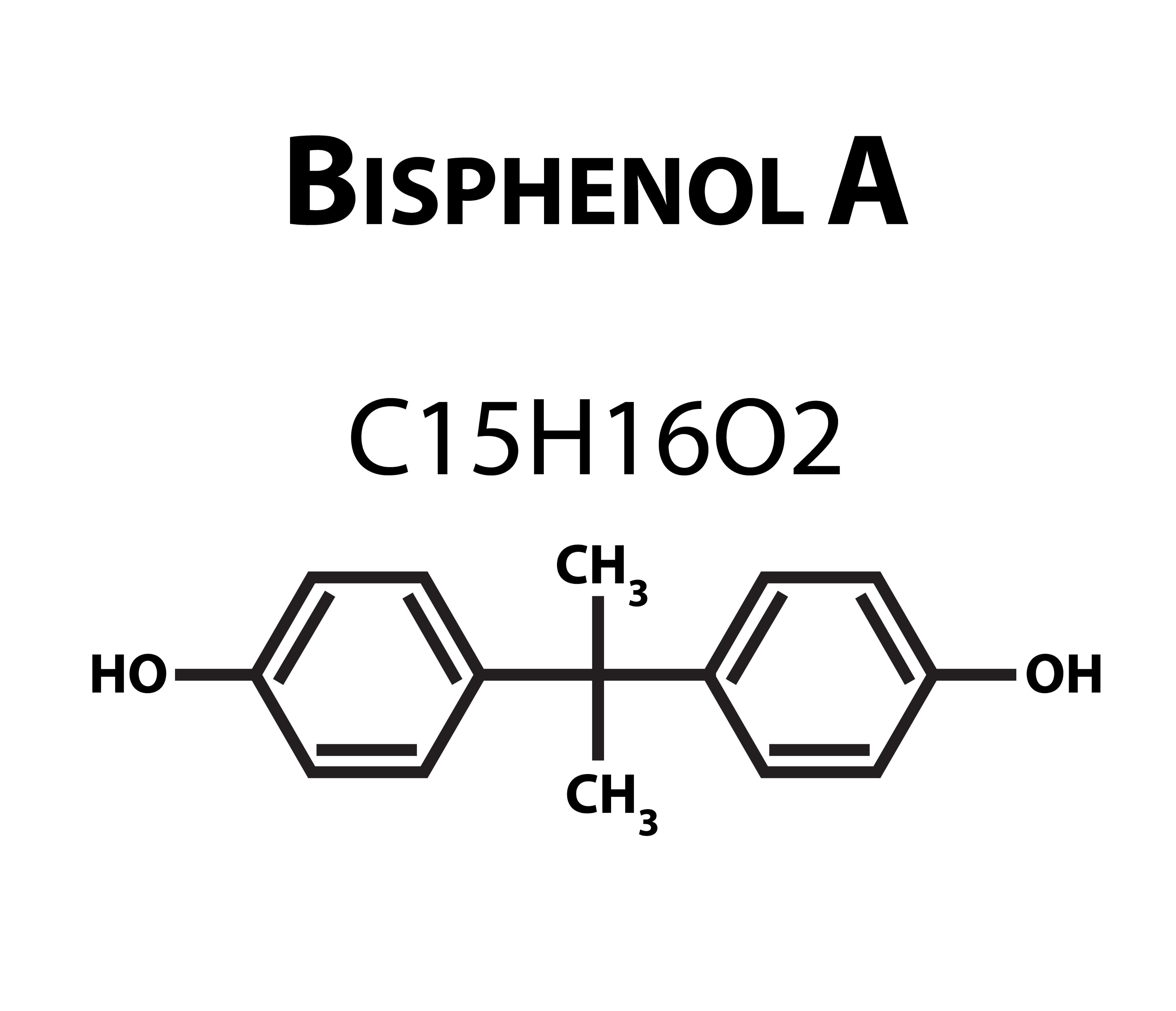

Risk of Chemical Leaching:

Evidence: According to reports from the U.S. Food and Drug Administration (FDA), certain plastics can release chemical substances like Bisphenol A (BPA) and Phthalates, particularly when exposed to high temperatures or prolonged contact with solvents. These substances have been shown to disrupt the endocrine system, posing health risks.

-

Explanation: Manufacturers use BPA to make plastic hard and transparent, while Phthalates are added to increase flexibility. However, their chemical bonds are not stable, making them prone to breaking down and leaching into the product.

-

Poor Preservation Capabilities:

Evidence: A study published in the Journal of Pharmaceutical Sciences indicated that plastic packaging has a significantly higher permeability to gases (especially oxygen) and moisture compared to metal.

Explanation: This allows oxygen molecules to easily penetrate the plastic's polymer layer, causing the active ingredients inside to oxidize. Similarly, light (particularly UV rays) can pass through transparent plastic bottles, degrading light-sensitive active ingredients, which can reduce their efficacy or change the product's color and smell.

-

Low Durability:

Evidence: According to packaging test standards from the American Society for Testing and Materials (ASTM International), plastic bottles are susceptible to cracking or breaking upon impact, especially in low temperatures.

Explanation: The molecular structure of plastic is less durable than metal, leading to poor impact resistance. This not only results in product loss but also damages the brand's image and credibility in the eyes of consumers.

Aluminum Pharmaceutical Bottles - The Comprehensive Solution for the Future

-

Ensures Absolute Product Safety:

Evidence: According to technical material documents, aluminum is a highly chemically inert metal. The natural aluminum oxide layer on its surface (and a specialized inner coating) creates a strong barrier that prevents aluminum molecules from reacting with the product inside.

Explanation: This inertness ensures that the pharmaceutical product remains uncontaminated and stable, preserving its original formula and efficacy. This meets the strict standards of regulatory bodies worldwide.

-

Optimizes Preservation:

Evidence: Aluminum has a nearly absolute barrier against gases and moisture. A study by the National Packaging Institute showed that aluminum bottles completely prevent the penetration of oxygen and water vapor, protecting the product from oxidation and hydrolysis.

Explanation: Aluminum is a metal, and like most metals, it is naturally opaque, not transparent. This opacity is a key benefit of using it for packaging, as it provides a complete barrier against light, particularly damaging UV rays. This protective quality is a major advantage over transparent or translucent plastic bottles, which allow light to pass through and potentially degrade the contents.

-

Enhances Brand Value:

A product packaged in an aluminum pharmaceutical bottle immediately creates an impression of professionalism, premium quality, and reliability. The sleek design, metallic finish, and flexible printing options help your product stand out in the market and build long-lasting consumer trust.

-

Environmentally Friendly:

Evidence: According to the International Aluminum Association, aluminum is one of the most highly recycled materials. Approximately 75% of all aluminum ever produced is still in use today. The process of recycling aluminum consumes only about 5% of the energy required to produce primary aluminum, which helps reduce massive plastic waste and contributes to sustainable development and corporate social responsibility.

Practical Applications of Aluminum in Pharmaceuticals

Pain Relief Spray: Aluminum bottles maintain excellent pressure, ensuring a consistent and powerful spray that helps the active ingredients penetrate the affected area quickly.

Mouth Spray: Given the high hygiene and safety requirements, aluminum bottles are the perfect choice for preserving the solution, preventing contamination, and maintaining a fresh flavor.

Mosquito and Insect Repellent Spray: The durable aluminum bottle won't break when carried on trips, ensuring users always have the product for protection.

Conclusion

Switching from plastic to aluminum pharmaceutical bottles is not just a packaging change; it's a strategic decision to guarantee quality, safety, and elevate your brand's position in the market.

Contact us today to receive a consultation on the best aluminum packaging solution for your product, helping it shine in the market and build lasting trust with your customers.

```

Please fill out the form below for support and consultation!