Aluminum Packaging for Pharmaceuticals & Nutraceuticals: Printing and Premium Branding

In the pharmaceutical and nutraceutical sectors, packaging is not merely a container but a mandatory information carrier throughout the product lifecycle. All information displayed on packaging is directly linked to safe use, traceability, and regulatory responsibility during market circulation.

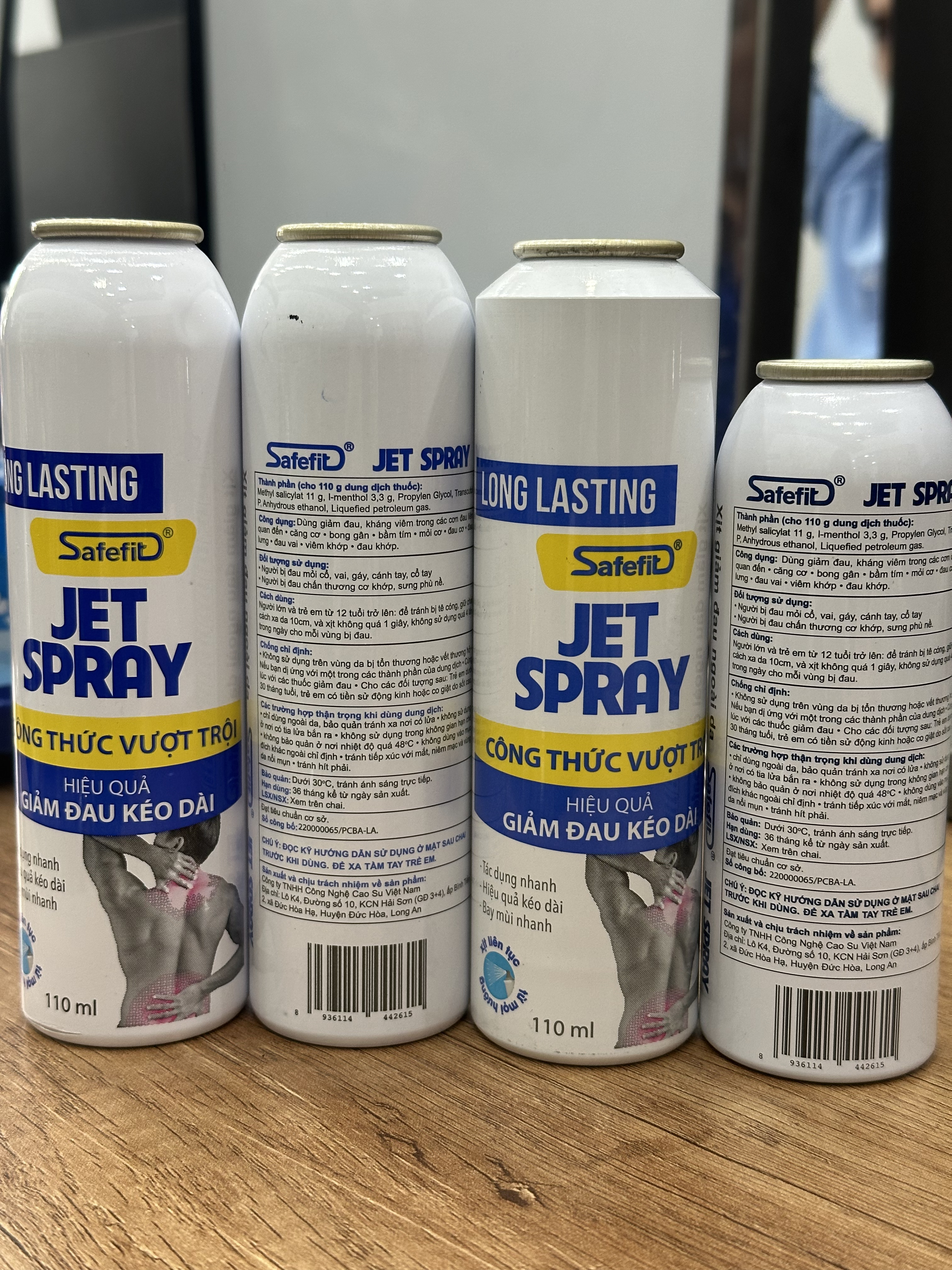

As regulatory requirements continue to tighten across many markets, aluminum packaging is increasingly used as a solution that ensures material stability, supports clear direct printing, and maintains consistent appearance throughout manufacturing, distribution, and use. For pharmaceuticals and nutraceuticals, printing quality and aesthetics are not purely visual elements but indicators of control level and packaging system reliability.

Printing on Aluminum Packaging and Its Role in the Pharmaceutical Industry

Information integrity

In pharmaceuticals and nutraceuticals, packaging concentrates all critical product information, including product name, composition, directions for use, safety warnings, and expiration date. This information serves not only end users but also quality control and regulatory compliance requirements.

If printed information becomes blurred, detached, or altered during storage and distribution, the resulting risks extend beyond user experience to safety and legal liability. This is especially critical for products with long shelf lives, where packaging must ensure that original information remains legible until the product is fully consumed.

Direct printing on aluminum packaging integrates information permanently into the material, reducing reliance on labels that are susceptible to humidity, abrasion, and prolonged storage. This is particularly important for pharmaceutical aluminum bottles, where usage and traceability information must remain stable throughout the product lifecycle. As a result, product information integrity is maintained consistently during market circulation.

Product traceability

Beyond user-facing information, packaging printing also supports traceability within the pharmaceutical supply chain. Data such as batch numbers, production dates, and product identification codes play a key role in inventory control, recalls, quality audits, and incident management.

When traceability information is printed directly and stably on aluminum packaging, control becomes more consistent across manufacturing, storage, and distribution stages. This reduces the risk of batch confusion and supports effective internal audits or recall procedures when required. As supply chains grow increasingly complex, clear traceability through packaging becomes an indispensable component of pharmaceutical and nutraceutical management.

Direct Printing on Aluminum Packaging: Operational Advantages

Consistency across production batches

In pharmaceutical operations, batch-to-batch consistency is a fundamental requirement. Even minor variations in packaging information or appearance can complicate quality control and data reconciliation.

Direct printing on aluminum packaging minimizes deviations introduced by intermediate steps such as label application. With information printed directly, companies can maintain consistent appearance and content across production batches, supporting inspections, evaluations, and quality reporting. This consistency not only optimizes internal operations but also meets the expectations of distributors and regulatory authorities in target markets.

Reduced risk of information errors

Information errors in pharmaceutical packaging can lead to serious consequences, from product confusion to safety risks. Direct printing on aluminum packaging helps limit the risk of mislabeling or unauthorized content changes outside controlled processes.

When information is permanently integrated into the packaging, risks associated with manual handling or label application errors are significantly reduced. This strengthens operational reliability and reduces control pressure during production and distribution.

Premium Branding in Pharmaceutical and Nutraceutical Aluminum Packaging

Professional appearance and controlled presentation

Aluminum packaging with direct printing provides a clean, uniform, and well-controlled surface. This appearance aligns with the professional distribution environment of the pharmaceutical industry, where packaging is often subject to close inspection prior to market release.

In this context, premium aesthetics are not about visual excess but about precision, consistency, and process control.

Integration of aesthetics and function

Clear printing and structured layouts help users identify products easily, reduce confusion, and support correct usage. Aesthetics therefore serve a functional purpose rather than being separated from performance, unlike many consumer packaging applications.

Practical Applications in Pharmaceuticals and Nutraceuticals

In practice, aluminum packaging is used for:

- Solid or semi-solid pharmaceutical products

- Nutraceuticals requiring quality control

- Products demanding clear information and consistent appearance

For these applications, durable printing and stable aesthetics support product management, regulatory compliance, and a professional image within distribution systems.

FAQ

Is aluminum bottle packaging suitable for pharmaceuticals and nutraceuticals?

Yes. Aluminum bottle packaging meets safety, traceability, and quality control requirements when manufactured under appropriate processes.

Why is direct printing on aluminum packaging preferred?

Direct printing ensures information remains stable and does not peel or fade during storage and transportation.

Does printing affect product safety?

No. When suitable inks and coatings for pharmaceutical use are applied, printing does not affect the product inside.

Is premium aesthetics necessary for pharmaceutical packaging?

Yes. Consistent appearance and clear printing reduce confusion and reflect a controlled distribution process.

Conclusion

For pharmaceuticals and nutraceuticals, aluminum packaging not only meets product protection requirements but also offers clear advantages in printing quality and premium aesthetics. Durable direct printing, clear information, and consistent appearance make aluminum packaging well suited to the quality control demands and professional distribution environments of the industry.