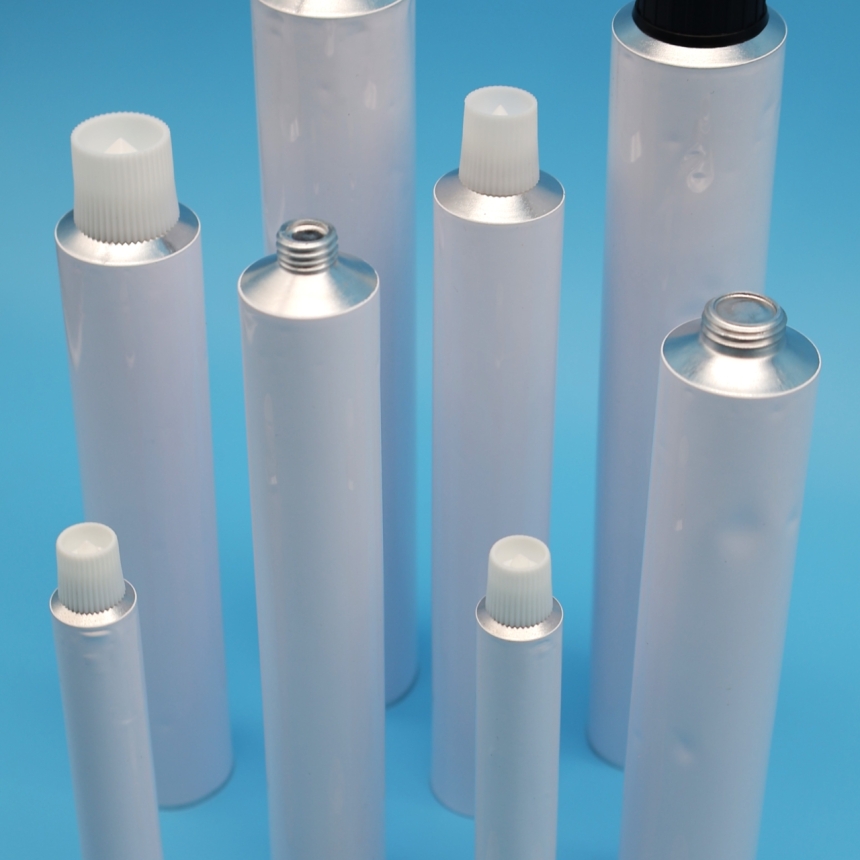

Premium Aluminum Tubes for Cosmetics & Pharmaceuticals: Certifications and Safety

Aluminum tubes used for cosmetics and pharmaceutical products must simultaneously meet requirements for contact safety, quality control, and market compliance across multiple regions. For products applied directly to the skin or used as part of long-term treatment regimens, packaging becomes an integral part of risk management throughout the entire supply chain.

As regulatory requirements continue to tighten across global markets, certifications and safety standards have become key criteria when evaluating packaging manufacturers. These factors are built on quality management systems that ensure consistency in production, distribution, and long-term quality control.

Certifications in Premium Aluminum Tube Manufacturing

Certifications serve as the basis for evaluating a manufacturer’s process control capabilities, especially in high-requirement industries such as cosmetics and pharmaceuticals. In practice, management standards such as ISO 9001 play a foundational role in establishing and maintaining quality control systems throughout the production process.

Certifications Linked to Process Control

In the manufacturing of pharmaceutical aluminum tubes and cosmetic aluminum tubes, certifications do not exist independently. They are directly tied to process systems. From raw material selection, tube forming, surface treatment, to final inspection, each stage must be consistently controlled under a quality management framework.

Operating under these standards helps reduce technical variation between production batches and enables traceability and corrective actions when issues arise, particularly in large-scale manufacturing.

The Role of Certifications in Factory Capability Assessment

For contract manufacturers and brand owners, certifications provide a reference point for assessing factory capability prior to collaboration. Quality management systems help standardize processes, reduce repeated audits from partners, and support production scale-up when demand increases.

Packaging Safety Requirements for Cosmetic and Pharmaceutical Aluminum Tubes

The safety of aluminum tubes must be ensured not only at the point of shipment but throughout the entire product lifecycle, from storage and transportation to end-user use.

Material Safety for Product Contact

Cosmetic aluminum tubes must not negatively affect the formulation inside, especially for products applied directly to the skin and requiring long-term stability. This requires appropriate control of materials, internal coatings, and factors that may cause interaction during use.

Proper material safety control helps reduce formulation degradation risks and supports consistent product performance through the full lifecycle.

Stability During Storage and Transportation

Premium aluminum tubes must maintain sealing integrity, shape, and structural stability under real storage and transportation conditions. This stability helps prevent leakage, deformation, or user experience issues, while supporting quality control across intermediate stages of the supply chain.

The Relationship Between Certifications and Practical Safety

Certifications and safety do not exist independently but directly reinforce each other throughout manufacturing and product use.

Certifications Supporting Risk Control in Pharmaceutical Applications

In pharmaceutical applications, requirements for safety, traceability, and risk control are significantly higher. For pharmaceutical aluminum tubes, these requirements are typically implemented through quality management systems such as ISO 9001 and pharmaceutical packaging standards like ISO 15378, ensuring compliance throughout the pharmaceutical supply chain.

Applying these standards correctly enables early detection of technical deviations and reduces the risk of incidents during market circulation.

Maintaining Consistency Between Production Batches

When factories operate under certified quality management systems, consistency between aluminum tube batches is better maintained. This reduces revalidation time for subsequent batches and supports production scaling without increasing risk, which is particularly critical for pharmaceutical products with strict compliance requirements.

Stability During Production Scale-Up and Multi-Market Distribution

When aluminum tubes are used for cosmetic and pharmaceutical products distributed across multiple markets, challenges extend beyond initial compliance to maintaining stability during production scale-up.

Preserving Packaging Performance as Volume Increases

During scale-up, aluminum tubes must retain original performance characteristics such as sealing, shape, and product protection even as production volume increases. Without proper control, small parameter changes can accumulate into significant deviations affecting real-world usability.

Maintaining stable characteristics helps reduce risks in repeat orders and supports long-term production planning for cosmetic and pharmaceutical brands.

Adaptability to Multi-Market Requirements

When the same aluminum tube is used across multiple markets, packaging must adapt to varying storage, transport, and usage conditions. Stability in tube design and structure reduces the need for adjustments when entering new markets, shortening implementation timelines and minimizing operational risk.

This adaptability is particularly important for pharmaceutical and cosmetic products with regional or long-term export strategies.

FAQ – Aluminum Tubes for Cosmetics & Pharmaceuticals

What does ISO 9001 mean for aluminum tubes?

ISO 9001 provides a framework for process control, helping maintain quality and consistency across aluminum tube batches.

When is ISO 15378 applied?

ISO 15378 applies to pharmaceutical packaging, addressing safety, traceability, and compliance requirements for drug packaging.

Are aluminum tubes safe for products applied directly to the skin?

Aluminum tubes are considered safe when materials and production processes are controlled according to cosmetic and pharmaceutical industry requirements.

Conclusion

For cosmetics and pharmaceuticals, premium aluminum tubes must be evaluated based on certifications and safety, not solely on external appearance. Selecting aluminum tubes manufactured under controlled processes helps reduce risk, maintain consistency, and effectively support distribution in markets with strict compliance requirements.